Woodworkers, we’ve got you. Whatever the project, we know how challenging it can be to choose the right tools – especially if you have limited experience with DIYing.

If you have carpentry tasks that need finishing up, or you need to attach trims or modify your furniture, there’s a good chance that a brad nailer is what you’re looking for.

If you’ve never used a brad nailer before, you might not know where to start. As with any new tool, there are various components to get to grips with, and of course, you need to know how to handle it safely.

That’s why we’ve put together this handy guide for woodworkers of all levels of experience.

Whether you’ve used a brad nailer before or you’ve never held one in your life, we’re confident that you’ll come away from this guide with all the information you need to finish up your project.

Without further ado, let’s dive right in.

What is a Brad Nailer?

First off, let’s start with the basics. A brad nailer is a type of nail gun that’s used to cut wood in woodwork and to put together small mouldings.

Brad nails are powered by electricity, and they usually work with 18 gauge brads to get the job done.

These pneumatic tools may look like a nail gun, but they don’t actually shoot nails. Instead, brad nailers shoot brads, which are a type of thing nail.

This is one of the biggest differences between brad nailers and finish nailers, and you often can’t use them interchangeably.

However, because these nail gauges are so small, you won’t have to worry about them splitting the surface of the wood.

Brad nails are also a very versatile tool; although they usually support 18-gauge brads, each brad can range between 5/9 to 2 ⅛ inch in length.

If you’ve ever seen a super small nail on a wood surface, there’s a good chance it came from a brad nailer! It’s also unlikely that you’ll ever need to refill a nail hole when you’re using brad nails, but if you do, it won’t be a difficult task.

To ensure your brad nailer works effectively, you’ll need to make sure you’re buying the right one. So, figure out what nails you need, and choose the easiest brad nailer for you in terms of maintenance and use.

This will give you better results, make your life easier, and hopefully prolong the life of your brad nailer.

We understand that this is a lot to consider if you’ve never used a brad nailer before, so we’re going to give you the full low down.

Your Guide to Choosing Brad Nails

So, if you’ve never used a brad nailer before (or even if you have), how do you choose the right nails for the job? Well, if you’ve taken a trip to the hardware store recently, you’ll have realized that there’s a staggering amount of nails to choose from.

So, before you buy nails for your project, take a read through this guide and get familiar with all the things you’ll need to consider first.

Before we start, there’s one important thing that you should know: Although many models look the same, certain nails have distinctive features that set each other apart.

This means you can’t pick up just ANY brad nail to complete your project.

Length

One of the most important things you’ll need to consider is the length of your nail.

So, how do you know what size nail you need to complete your project? Well, to make your life easier, there are two rules you should be following.

Firstly, you’ll need to make sure that your brad nail is at least three times as long as the material you’re going to be nailing through.

Secondly, you’ll need to ensure you’re using a nail that DOESN’T go the whole way through your material. Instead, you should be choosing a length that goes at least three-quarters of the way through your material.

Establishing the right length can be a little tricky, but one thing’s for sure – using a brad nail that’s too long is better than using one that’s too short. If in doubt, always opt for a longer nail

Sizing

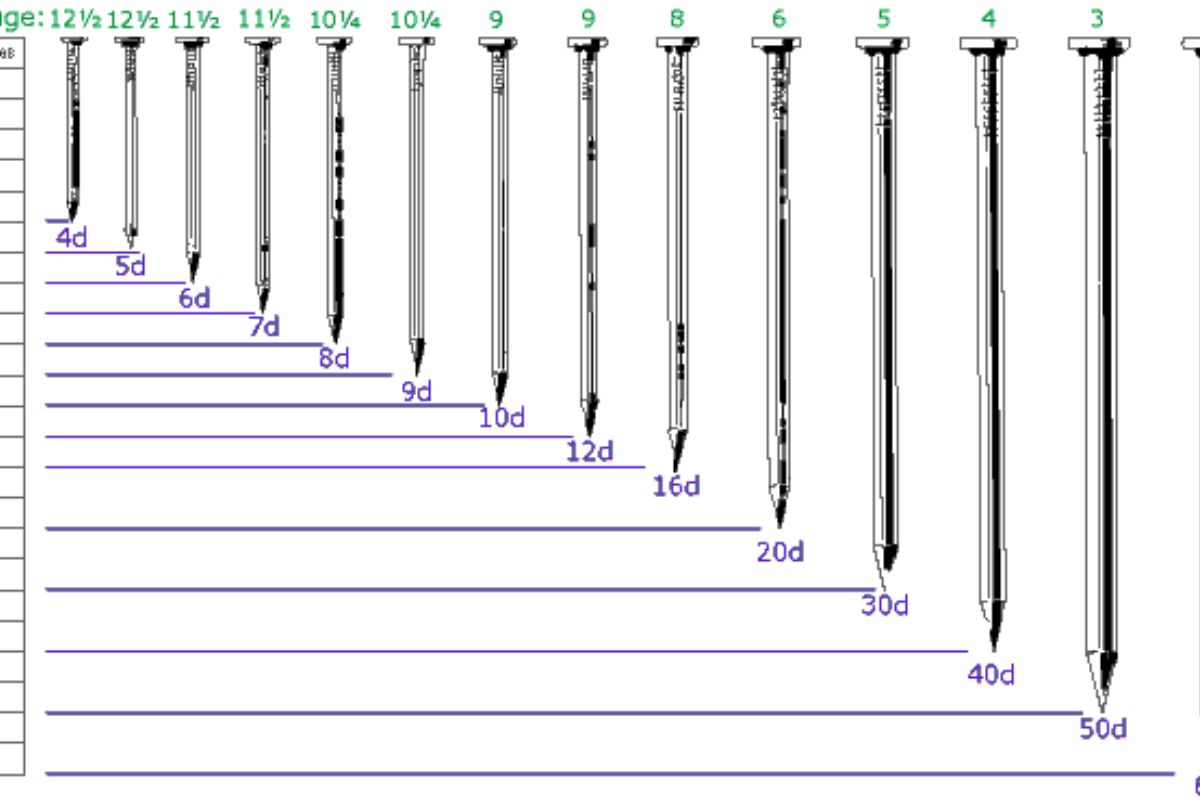

Next on your list of considerations should be sizing. Brad nails come in a range of different sizes, and they’re sold according to penny size.

If you take a look at a list of brad nail sizes (such as 8d, 16d, and so forth), you’re probably wondering… what the heck does the d stand for? The d represents the penny of British currency.

So, when you hear of brad nails being sold according to penny size, the d simply describes the length of the nail. The larger the number, the larger the nail. Don’t worry – it’s simpler than it sounds!

When we’re thinking about size, there’s another factor to consider – gauge. The gauge of your brad nail refers to the thickness of your nail, not the length.

Different length brad nails can come in different gauges, but the 18-gauge is the most popular, and woodworkers prefer it for its versatility.

Shank Patterns

Another thing to think about is shank patterns. Different brad nails can come with different shank patterns, and it’s important to know what these are and how to use them.

Here are the three most common shank patterns found on brad nails and what they mean.

- Standard: If your brad nail has a smooth shank with no patterns, it’s an all-purpose brad nail. These can be used for a variety of projects.

- Ring: Ring nails will have distinctive ridges and grooves seen on the shank. Ring nails can be used for roof decking, especially because their grooves add extra holding power, making them popular for tough tasks where extra strength is needed.

- Spiral: Lastly, we have the spiral nail. These nails typically spin when they’re shot from the nailer, giving them far more holding power than traditional nails. This makes them great for heavy-duty tasks, and there’s virtually no chance that they’ll split your wood.

Interior or Exterior

Whatever your project, you’ll be using your brad nails either on the interior or exterior of a material.

Interior and exterior nails are designed for specific purposes, and if you use interior nails on the outside of a material, they’ll probably rust quicker, bleed through your paint, and wreck your project.

So, if you’re looking for the right exterior nails, it’s best to choose one of the following options:

- Electro-Galvanized: These nails are reinforced with a coating of zinc, making them less susceptible to rust.

- Stainless-Steel: Stainless steel nails are pretty much guaranteed not to rust. If your project is going to be exposed to water or the elements, we’d recommend using stainless-steel nails.

- Hot-Dipped-Galvanized: Hot-dipped galvanized nails have been treated with molten zinc. This makes them incredibly resistant to corrosion and are great for use with pressure-treated wood.

Brad Nails: Knowing the Features

As we discussed earlier, there are so many different nails on the market, that knowing where to start can be a challenge. If you want your project to succeed, you’ll need to make an informed decision when you’re making a purchase.

The features of your nails will determine how well they perform and play a big role in the longevity of your project. Here are the most important features of brad nails that you need to know:

- Nail Point: There are different types of nail points, including diamond, long diamond, and blunt. Diamond point nails are the most popular type of nail point. Choosing the right nail point will make it easier to drill your nail into your material.

- Nail Head: There are four types of nail head to choose from – flat head, checkered flat head, countersunk head, and cupped head.

- Nail Shank: Lastly, you’ll need to consider the nail shank. As we’ve discussed, there are different types of shanks that can be used for different purposes.

The Brad Nail Size Chart

Before you head off to buy your brad nails, let’s talk sizes. There are many different types of brad nails on the market, and each one will come in a different size and a different gauge.

To choose the right nail, you’ll need to consider the nail lengths and gauge, as using the wrong nail can cause significant damage to your work surface.

As you can see from the chart above, in terms of length, the smallest numbers represent the smallest nails. For example, a 4d nail is much shorter than a 12d nail.

However, when we’re considering gauge, it’s a different story, and smaller numbers actually represent a thicker gauge.

So, if you’re looking for a short nail with a thick gauge, remember: the small number (such as 7d) will mean a shorter nail, but for a thicker gauge, you’ll need a smaller number, like a 2.

If you’re ever unsure which nails to use, we’d recommend visiting your local hardware store, and talking to a member of staff for more information.

Simply discuss the details of your project, what materials you’ll be using and what nailer you have, and they’ll be able to point you in the right direction.

How to Buy the Right Brad Nailer For Your Project

Depending on the task at hand, you may now feel ready to go out and buy the right nails for your project.

There are many different sizes, points, shanks, and lengths to choose from, so be sure to do your research before you make a purchase.

If you’ve got a selection of projects to work on, we’d recommend buying an assortment of nails. Most hardware stores will sell assortments in boxes to save you buying your own selection of different nails.

Even if you don’t use them all, you never know when you’ll need some spare nails to hand to fix things up around the house! All brad nails are well treated and don’t expire, so no matter how long they sit in your cupboard for, they’ll always be ready to serve their purpose.

If you’re new to using brad nailers, though, we still have some important information to run through.

Choosing the right nails is the perfect starting point, but how do you actually load them into a brad nailer and use the tool to complete your project?

How Do You Load a Brad Nailer?

Okay, woodworkers. Nails at the ready – it’s time to load up your brad nailer! Learning how to load up a brad nailer is one of the most important steps in the process.

After all, you won’t be able to put the nails in your wood if you don’t know how to load your tool!

Although brad nailers can be used for different purposes, they’re most commonly used to put nails in plywood, hardwood, and other manufactured wood products.

When you’re working on different materials, this is important to remember, and it reminds us how important it is to load up your nailer with the correct number of brads. Closing your magazine correctly is also a significant step.

Before you start working on your project, you’ll need to know the key elements of loading a brad nailer. These are:

- Depth Gauge: Your depth gauge is used to adjust the distance between your nailer and your work material.

- Magazine: Your magazine is where the brads are inserted into the tool.

- Magazine Lock: Once you’ve loaded your brads, the lock is used to secure them in place and get your nailer ready for action. The lock must be pressed to use the gun. At the other end of the magazine is another lock which is used to eliminate jammed brads from your tool.

- Air Pressure Dial: The air pressure dial determines how much air is released when you press the trigger. Using more air pressure will push your brads in deeper.

There are many models of brad nailer, and as you’d expect, they don’t all load the same. Getting familiar with your own tool and following the manufacturer’s guidance is the best way to learn.

Although different brad nailers load up differently, there are several features that remain the same across the board, including:

- Push Forward: This involves pushing the brad strip towards the firing end of the nailer. The push forward function is usually always the same on each brad nailer. However, the brad strips may look different depending on the model.

- Continuous Strips: The continuous strips should always be carefully handled to ensure they don’t break.

- Brad Length: You’ll always need to ensure that your brads are the right length. If your brads are shorter than the lower end of the range, they may fit in the magazine, but there’s a good chance they won’t fire and will jam inside your nailer.

- Side Magazine: If you’ve never used a brad nailer before, avoid this beginner mistake – slamming the side magazine shut. Although you might be tempted to slam it shut and get ready to nail, using too much force can actually cause your nailer to jam. It could even dislodge your brad strip.

There are some accessories you’ll need to get your hands on before you even consider loading a brad nailer. These include:

- The right sized brads

- Goggles

- Nail gun

- Power Supply

If you’ve considered all of these points and got your equipment to hand, you’ll be ready for action. Here’s how to load your brad nailer.

Read Instructions and Prepare

Read through the instructions of your nailer carefully, and consider all of the safety instructions. Check whether the air hose needs to be connected or disconnected, and ensure you have the right equipment to hand.

Get the Air Holes Ready

If you need to connect your air holes, you can do so with Teflon tape (Also check out this Flex Tape Review). If necessary, ensure the airhole is tightened to avoid any air escaping.

Open Magazine

Now, depress the cartage on your nailer and open the magazine. You’ll need to pull it back to access the magazine.

Load Brads

You’re now ready to load your brads. Start by ensuring the head of the brad fits comfortably into the slots. You’ll probably notice several grooves to fit different-sized brads, so make sure you’re putting them in the right grooves.

Load several brads into the brad nailer and ensure they fit comfortably.

Remember to avoid overloading your magazine. Your manufacturer will specify how many nails can be loaded into your nailer at one time – under no circumstances should you exceed this limit.

Close Magazine

Now, go ahead and close your magazine. Side it shut until it clicks in place.

Check the Loading Mechanism

The loading mechanism may differ depending on the type of nailer you’re using. Some may load from the side, while others may load from the top. Regardless of how your nailer loads, make sure the brads fit correctly inside the tool.

Tips for Using Your Brad Nailer

Once you’ve finished loading up your brad nailer, you’ll be ready to go ahead and use it. Before you do, here are a few things to bear in mind.

First off, remember that different types of wood can split differently. Before you start work on your main project, we’d advise practicing with different types of wood.

This will give you an idea of how closely you can work to the end of the grain without splitting it.

You should also remember that brads are thin, and there’s a good chance that some nails won’t go into the stock. Some brads may also bend easily under a hammerhead, so you’re unlikely to be able to fix ill-fitting brads in this way.

If you ever need to remove a brad, we’d advise using the brad nailer to do so.

How Do You Use an Electric Brad Nailer?

Your electric brad nailer will either be corded or cordless. If you’re yet to buy a brad nailer and you’re looking for a cost-effective option, corded models are probably a cheaper option.

Like manual nailers, these tools are intended to fire brads into wooden surfaces. Eighteen gauge brads are the most common. Whether it’s corded or cordless, your nailer will have the following features:

Electric Brad Nailer: Key Features

- On/Off Switch: The on and off switches are used to power up and shut down your nailer.

- Double Insulation: Double insulation will prevent the need for a three-wire grounded power cord.

- Depth Gauge

- HI/LO Power: HI/LO power works in different ways. You can use HI power to shoot brads into harder surfaces, and the LO power option can be used to push them into softer materials.

- Air Pressure Dial:

- Magazine: The magazine is the component that you load your brad nails into.

- Flush Nailing: Flush nailing has a stapling tacker that fits flush against obscure or perpendicular surfaces.

- Magazine Lock: Your magazine lock is used to load the nailer and secure the brads in place. There are two locks on a brad nailer, but the magazine lock secures them in place, while the other lock is used to clear out jammed brads.

The Key Functions of an Electric Brad Nailer

- Repairing furniture such as cabinets

- Trimming the interior of windows and doors

- Fitting quarter-round and baseboards

- Crown molding

These are the most common uses of electric brad nailers. However, you should not attempt to use an electric nailer to tack up insulation or any thin material such as plastic sheets.

Electric brad nailers may also not be suitable for construction works or for securing framing on a home.

If you need a tool for these projects, we’d recommend using a framing nailer with a coil magazine.

A Note on Safety

Using an electric brad nailer is simple. However, you’ll still need to take care when you’re loading your brad nailer and using it on your project. They’re quicker and more efficient than manual nailers, but they can carry more risks.

Before you use an electric nailer, read through the manufacturer’s instructions, and always have a first aid kit to hand in case of an accident.

How to Load an Electric Brad Nailer

Before you start using your electric brad nailer, you’ll need to load it. Follow the steps below to load up an electric brad nailer:

- Ensure your tool is unplugged and switched off.

- Make sure you’re using the right size brads for your nailer. Inappropriate sizes can cause your nailer to jam.

- Hold your nailer upside down, and slowly start to place your brads in the magazine. Make sure you’re tilting your nailer at an angle to position the brads against the channel’s wall.

- When you’re done, slide the magazine latch backward while securing the brad strip in place.

- Lock the nails securely in the magazine.

Setting Up and Using Your Electric Nailer Safely

Now you’ve finished loading your electric brad nailer, you’re ready to get started. To use your electric brad nailer safely, we’d recommend following these steps:

- Secure your material or workpiece on a stable surface. You can use clamps to do this.

- Make sure your brad nailer is switched off.

- When you’re ready, turn the nailer on and press it firmly into your material. This will kick the safety mechanism into action.

- When you pull the trigger, make sure you’re applying the right amount of pressure to the knob.

- Lastly, make sure you read all of the instructions provided. Never attempt to use an electric brad nailer without reading through the instructions.

To keep you safe, follow the instructions below:

Electricity Supply

- Keep the nailer away from water

- Don’t use a nailer with a damaged cord

- If you’re using the nailer outside, use an extension marked ‘W-A’ or ‘W’, which will be rated for external use.

Work Area

- Keep your work area clean and well lit

- Get rid of any distractions that may cause you to lose control when you’re drilling

Maintenance

- Don’t lubricate your tool – it’s designed to work without it

- Avoid using solvents to clean the tool as this can erode plastic components

Protecting Your Personal Safety

- Wear goggles, a mask, and hearing protection

- Don’t use your tool if you’re under the influence of drugs or alcohol

- Wear the right footwear to stay balanced

Pneumatic Brad Nailers: How Do You Use Them?

Pneumatic nailers are usually powered by an air compressor, and they quickly fire nails into your desired surface.

Some of the most important equipment you’ll need to get started with your pneumatic brad nailer includes:

- Air hose and an air compressor

- A hose adapter

- Teflon tape

- A tack cloth

- An adjustable wrench

- Pneumatic tool oil

If you need to use a pneumatic brad nailer for your project, let us walk you through the most important steps in the process.

Thankfully, using a pneumatic brad nailer is simple, even for inexperienced users!

Connect Hose Adapter

First off, you’ll need to ensure you have the right hose adapter for your brad nailer. Once you’ve sourced the right adapter, you can go ahead and connect it to your brad nailer.

Make sure it’s nice and tight, and if it’s not, use an adjustable wrench to secure it in place.

If you want some extra security, you can go ahead and secure it in place with some Teflon tape to prevent air leaks.

Lubricate

Now, you’ll need some lubrication. Your brad nailer will need to be lubricated before every use, so, get your tool lubricant ready and lubricate the metal parts of your hose adapter.

You’ll need no more than a few drops to get the job done. Wipe off any excess with a tack cloth.

Load Up

You can now go ahead and load up your brad nailer. Before you start, make sure you have the correct nail size and count for your task.

Connect to Air Compressor

Next, attach your air compressor to your brad nailer. Allow your compressor to pressurize before connecting it.

When you’re ready, secure your air hose to the nailer, and make sure it’s tight enough to avoid any air leaks. If things feel loose, tighten them up with a wrench.

Test and Proceed

Before you get to work, test your brad nailer on a wooden surface. Hold your nailer with the nose at a 90-degree angle, and pull the trigger to let the nail enter the wood. If it goes in, you’re ready to start on your project!

Good to Know

Whether you’re using a corded, electric, or pneumatic brad nailer, your tool needs to be handled with care. If you’re unfamiliar with brad nailers, always read the manufacturer’s instructions before you start.

Not all brad nailers are made equal, so even if you know how to use one model, don’t assume you’ll know how to use them all!

It’s also important to consider your nail length. Ensure you’re using the right-sized nails for the job. Otherwise, your project is likely to fail, and you risk damaging your nailer.

Maintaining Brad Nailers: Here’s What You Need to Know

Once you’ve bought yourself a brad nailer and you’ve learned how to use it, you’ll be feeling accomplished and ready to tackle your project.

Congratulations! However, the work doesn’t stop here. Like any tool, you’ll need to know how to maintain your brad nailer to prolong its life and keep it safe and functional.

Without the correct care and storage, your nailer is unlikely to stand the test of time.

To keep your brad nailer working as well as the day you bought it, take these tips on board:

Lubricate During Use

Keep any metal moving parts lubricated when you’re using your nailer. This will prevent your nails from jamming. You’ll only need a few drops to do the job.

It’s also worth lubricating the air hose before you get to work. You can blank fire yor nailer a few times to get the oil moving through the nailer.

If you’re using your nailer for a long period of time, remember to lubricate as you work.

Remember to use the right oil for your nailer, as the wrong oil can erode the nailer, especially its rubber components.

Store Carefully

Keep your brad nailer stored carefully. Avoid keeping your brad nailer in places with lots of moisture and salt, such as coastal areas. This can prevent the tool from functioning.

Remember to invest in a quality airtight case for your nailer, too. This will keep it safe and secure when you’re not using it.

Learn to Handle it Correctly

Always follow the instructions in your user manual. Once you know how to handle the tool, make sure you use the right size nails for the job, as the wrong amount of pressure and ill-fitting nails can damage your brad nailer.

You should also make sure you have the right size air compressor to do the job. If you’re unsure which air compressor you need, consult your manufacturer’s instructions for more information.

Tighten All Bolts and Screws

Last but not least, you’ll need to make sure you’re keeping your bolts and screws nice and tight. If you’re using your brad nailer regularly, we’d recommend tightening all of its screws and bolts at least once a month.

If your bolts and screws continue to loosen over time (which they will, with the vibration!), you risk damaging your nailer.

It’s SO important to keep all of your bolts and screws tightened. If any loose screws fall out of your nailer during use, you also risk injuring yourself.

Whether they’re manual, electric, or pneumatic, brad nailers are a big investment. You’ll need to maintain your nailer regularly, following the steps above, to ensure it continues to function well.

If you don’t maintain it, you’ll have to keep buying new brad nailers, and that’s a lot of money to be throwing away if you can avoid it!

Final Thoughts

No matter the project, a brad nailer can help you get the job done. Even if you’re an inexperienced DIYer, using a brad nailer is pretty simple. With the right maintenance, your brad nailer can last you a lifetime, so whatever projects you decide to tackle, you’ll be prepared!

Before you get to work, just remember to take the appropriate safety precautions, and always read through the manufacturer’s instructions before you start.

We hope you’ve enjoyed reading through our comprehensive guide on brad nailers, and we can’t wait for you to get started!

- The Woodworkers Guide to Brad Nailers: Everything You Need to Know - September 25, 2023

- How To DIY An Aztec Garden Dining Table [The Easy Way] - October 18, 2022

- Farrow & Ball Pigeon: Is It Right For Your Home? - October 17, 2022