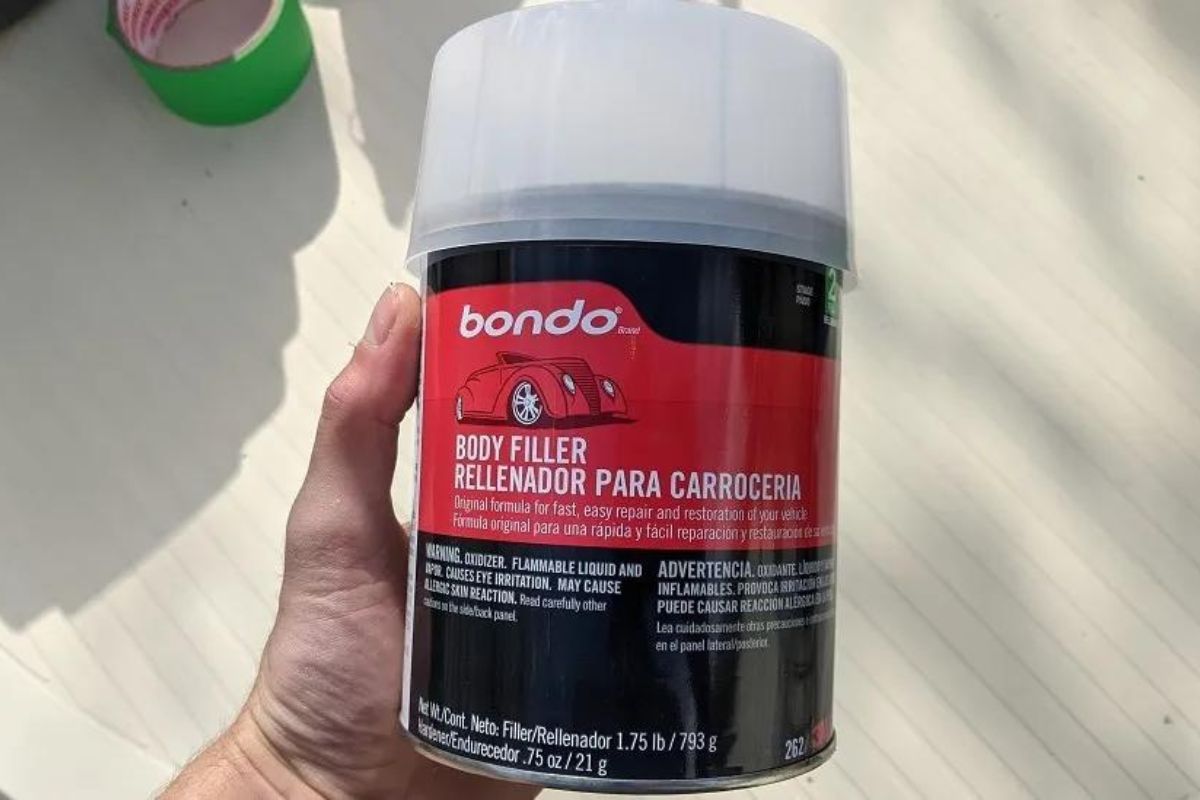

Originally marketed and sold as an automotive putty filler designed for car repairs, Bondo has gone on to become one of the leading brands of adhesive, quick drying putty in the US, and is used for any number of applications – ranging from automobile repair, boat repair, and for home improvement.

But what exactly is Bondo made of, and how long does it take to dry?

What Is Bondo Made From?

The original recipe for Bondo was developed in 1955, and was born from a long and storied history of automotive repair.

Initially, mechanics would use molten lead to create sturdy repairs on vehicles during the First World War and the surrounding years, but this changed during the Second World War, when various DIY plastic solutions were developed to allow sufficient, long lasting repairs to be conducted at home.

Bondo’s ingredients consisted of talc (talcum) and plastic, which were combined to create a resin that had a hardening element added.

This process has remained very similar since its inception, and provides long lasting durability to automobiles, boats, and other industrial and domestic repairs – using a modern combination of polyester resin, fiberglass reinforcement, and various fillers.

What Is The Drying Time?

One thing that changed the game for automotive repairs was the introduction of quick drying resins that didn’t require molten metal or extreme heat to work.

This not only meant that panel beating and the risk of warping panels became a relative thing of the past, but that people could easily conduct their own repairs at home without the help of a professional.

Drying Time

In the case of Bondo, the drying time is between 15 and 30 minutes under normal conditions – roughly speaking, around 25 degrees celsius (or 75 degrees fahrenheit). After this point it is perfectly fine and sturdy enough to sand down and create a smoother edge.

Curing Time

Bondo takes about 45 minutes to properly cure under normal conditions, and after this it is perfectly okay to begin the respraying or painting process.

What Does ‘Cure’ Mean?

With regards to resins and other such materials, the curing process refers to the shift from a low molecular state to a highly cross-linked state.

This change in state is a chemical reaction, which once complete means that the resin becomes more rigid and static on a molecular level – making it firm and solid.

Drying Vs Curing

Despite providing comparable functions, there are differences between the drying process, and the curing process – at least when it comes to chemical compositions like resin and cement.

Drying refers to providing the material with adequate moisture conditions- that is, facilitating a state wherein there is enough moisture to allow natural movement, and room for the concrete or resin to breathe.

Curing on the other hand, involves providing the proper time, moisture, and temperature for the concrete or resin to achieve the conditions wherein it becomes suitable for its intended use.

Can You Expedite Drying Time?

The drying time of Bondo can be sped up somewhat, with the use of a hair dryer or heat gun. However, it is important not to heat it up too much, as this could cause it to become brittle and unfit for purpose.

This means holding the hair dryer or heat gun far enough away from the Bondo to ensure this doesn’t happen.

When using a hair dryer, hold it about 6 inches away, and when using a heat gun – which is capable of achieving much hotter temperatures – hold it 12 inches away from the Bondo.

When using these methods to expedite the drying process, be sure to move them back and forth instead of remaining static.

This will stop the individual spots from becoming too hot, and will encourage a more balanced, even consistency once completed.

What Can Slow Down Drying Time?

There are several environmental conditions that can slow down the drying time, some of which are avoidable, and some that aren’t.

Humidity

If the weather where you are is humid, or if it is humid in your work area, then this can drastically slow down the drying process, something that is not ideal when you are shooting for a quick, solid hold.

This is because humidity creates too much moisture, keeping the resin in a liquid state for longer than normal.

Cold Temperatures

The same is true for cold temperatures, which can keep the Bondo in a liquified state for much longer than normal.

Sometimes this cannot be helped – for example if you live in a cold environment – and this is where it can be useful to use a hair dryer or a heat gun to expedite the drying process.

Thickness

The thickness of the solution will also play a part in the drying time, and thus it is important not to assume it is perfectly dried and cured just because the recommended waiting time has elapsed.

How To Make Sure It Is Dry

This might sound obvious, but the best way to be confident about your Bondo being dry and cured is to wait and give it time.

If you are working in your own garage, then ensure it is at room temperature, and give the solution plenty of time to go to work.

If you are working outside, then working during the day would be preferable as it is warmer, and be sure to use various methods (such as dryers and heat guns) to help the whole process along.

Final Thoughts

And there we have it, everything you need to know about Bondo, and how long it takes for it to dry.

Bondo has been incredibly useful in making home and automotive improvements accessible to the average person, and means that in no time at all you can have industry standard repairs with minimal effort and expense.

- The Woodworkers Guide to Brad Nailers: Everything You Need to Know - September 25, 2023

- How To DIY An Aztec Garden Dining Table [The Easy Way] - October 18, 2022

- Farrow & Ball Pigeon: Is It Right For Your Home? - October 17, 2022