Anyone who has worked with concrete will know the importance of using concrete forms – not only as a means of maintaining moisture levels, but also for ensuring proper finish on the end product.

And the proper use of forms is really half the battle, and keeping them on for too long (or too little) could have detrimental effects to the overall quality (and longevity) or your concrete surface.

But what exactly are concrete forms used for, and how long should they be left?

What Are They Used For?

The viscous nature of wet concrete means that, until it has sufficiently dried and become strong, it needs something to support it and keep it aligned.

This is where concrete forms come in, and they provide the wet concrete with a sufficient framework that keeps it in place until it can stand on its own.

Think of it as a jello mold – if the mold is removed before the mixture is dried, then the jello will run everywhere and not maintain a shape.

However, with the right amount of support, time, and temperature balance, it will maintain its firmness.

What Are They Made Of?

There are many materials that concrete forms are made from, although tend to be made from cheap pallet wood, or some equivalent, that can then be discarded once the job is done.

Another commonly used material, at least on official construction sites, is timber.

This is because timber is relatively cheap, flexible, lightweight, and durable, making it the perfect substance to accommodate and control the wet concrete during these crucial stages of the process.

Other materials used for making concrete forms include resin bonded plywood and steel – the latter of which is generally used in heavy construction, such as buildings and skyscrapers, which require a particularly strong and rigid form to maintain their precisely designed shape and dimensions.

Important Attributes Of Concrete Forms

The widespread use and importance of concrete means that specific attributes are required when choosing a suitable form material.

Strength

Especially in heavy construction, the forms need to be strong enough to support tonnes of wet concrete and to hold them in their place.

The lack of strength could result in warping, imperfections, and weakening of the concrete’s efficacy.

They also need to be able to withstand the outward force of the concrete, which can be subject to temperature and volume changes depending on the environment.

If the forms aren’t strong enough, then the concrete could pour out of the mold before it has properly dried or cured – thus rendering it unusable.

Lightness

The forms also need to be lightweight, so as to be able to move when the process is complete.

This also makes them easier to dispose of, and means that there isn’t any damage done to the concrete when they are trying to remove and get rid of them.

The lightness is also important for the users, who will have to set them up before the concrete can be poured inside.

Flexibility

Flexibility might not sound like an advantage, but there needs to be a small degree of it to allow the concrete to be poured inside, and to accommodate for the changes in shape of the substance when in the mold.

No flexibility at all would run the risk of breaking the forms, or causing resistance damage to the concrete as it dries – potentially hindering the structural integrity of the finished product.

How Long Should They Be Left For?

Concrete forms, generally speaking, should be left for approximately 48 hours to ensure that the outer layers of the concrete have achieved rigidity.

Of course, the amount of time the concrete needs to dry depends entirely on the conditions of the environment.

If the weather is humid, then the drying process will take longer, as the moisture levels will be too high. Similarly, cold temperatures can also be detrimental to the finished product.

Speaking purely on a technical basis, high quality concrete can take anywhere up to 28 days to fully cure. It is at this point that the molecular bonds are at their strongest, and the concrete becomes at its best.

While the drying process happens much sooner, it is still not at its strongest form until after a matter of several weeks – temperature dependent of course.

Can Concrete Forms Be Reused?

While on a professional level the forms might not be reused – at least in heavily industrialized settings – most independent contractors will probably reuse them as much as they can.

This is both a cost saving exercise, as well as for saving the time and energy needed to make new ones every time.

Granted, if the job was a one off, and the dimensions are no longer useful, then they might be discarded, but for repeat jobs they can come in useful.

What Would Happen Without Forms?

Especially in professional settings, such as within heavy industry, forms are highly responsible for creating a great finished product. And without them, the industry just wouldn’t be the same.

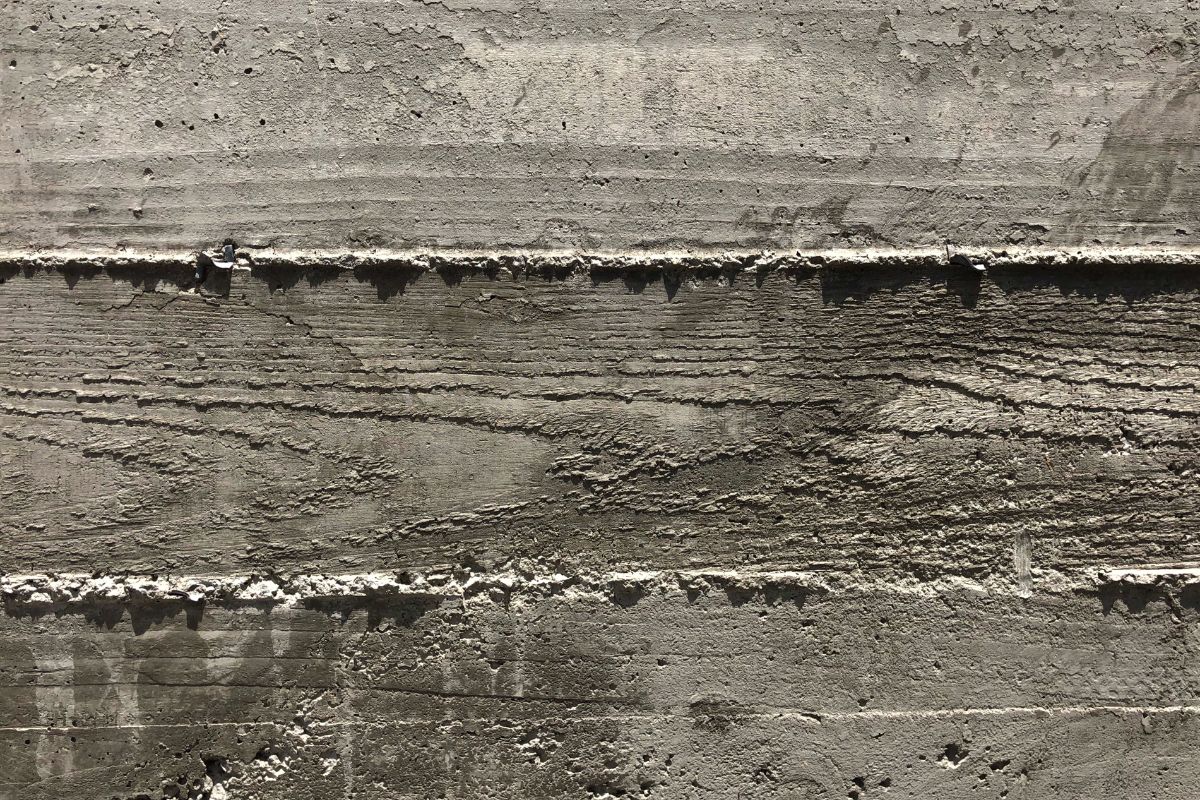

Warping

Without sufficient support, concrete would not be able to maintain a uniform shape, and as such warping would occur. This could mean the difference between usable foundations, and losing a lot of time and money.

Weakness

Without proper support, concrete wouldn’t be able to dry properly, thus the molecular bonds would not be strong enough to create the firmness associated with good concrete.

This isn’t good from a construction standpoint, and can even prove really dangerous.

Non-Uniformity

Depending on the application of the concrete, it would also be impossible to establish uniformity with the concrete.

This is because of the sheer weight and movement potential with wet concrete, which without proper support would not be able to remain in the desired shape.

How Else Is Concrete Maintained?

Maintaining the temperature and moisture levels of the concrete are two of the most important elements to focus on when trying to create a perfect concrete surface.

Without properly maintaining these two things, then the concrete in question may not have the desired longevity, strength, or durability.

The Importance Of Temperature

As with humidity and coldness, extreme heat can also cause severe damage to concrete, decreasing the drying time to such an extent that the dried concrete becomes brittle, weak, and non-durable.

The Importance Of Moisture

One thing that might surprise most people about concrete, is that it is never actually completely dry – at least not on a molecular level.

What makes concrete so durable is its ability to bend and move with the natural migration of the soil and earth around it, and this is maintained by getting the moisture levels right during the initial drying and curing periods.

Forms actually come in handy for ensuring moisture, as they can be used to facilitate ‘pond watering’, which involves flooding the top of the concrete (within the forms) with water, some of which will then be absorbed by the concrete, and the rest of which will either evaporate or be swept off when the forms are removed.

Final Thoughts

And there we are, everything you need to know about concrete forms, their importance to the construction industry, and the amount of time they need to be left.

What is abundantly clear is that, without forms, concrete would be nowhere near as useful a material as it currently is, and we wouldn’t be able to create as many things.

So, the next time you find yourself needing to work with concrete, consider what material would work best for you, and be sure to give it plenty of time to dry and cure before proceeding!

- The Woodworkers Guide to Brad Nailers: Everything You Need to Know - September 25, 2023

- How To DIY An Aztec Garden Dining Table [The Easy Way] - October 18, 2022

- Farrow & Ball Pigeon: Is It Right For Your Home? - October 17, 2022